Understanding the Two-Stage Steam Absorption Chiller: Efficient Cooling with Water and Lithium Bromide

Two Stage Steam Absorption Chillers

In this blog let us explore the basics of fascinating world of two-stage steam absorption chillers, which utilize water

as the refrigerant and lithium bromide as the absorbent to achieve remarkable

cooling efficiency. Learn how this cutting-edge refrigeration technology

operates through a continuous cycle divided into six crucial steps. From

solution pumps and heat exchangers to condensers and absorbers, understand the

intricate process of creating an extreme vacuum that drives the refrigeration

effect. Discover the benefits of this green technology and its superiority over

conventional systems in terms of efficiency and operational simplicity. Ideal

for anyone interested in HVAC systems, energy efficiency, and sustainable

cooling solutions.

How it works ?:- Steam Machines

Remarkably

efficient two stage absorption refrigeration cycle uses water as the

refrigerant and lithium bromide as the absorbent.

It is the

strong affinity these two substances have for each other that makes the cycle work.

The entire process occurs in hermetic vessels in almost complete vacuum.

The large

diagram above indicates the complete chilling cycle.

The six

steps are detailed below, with "corresponding numbers in the diagram to

show where each step takes place.

Two stage

absorption chilling cycle is continuous; however for the sake of clarity and

simplicity, is divided into six steps.

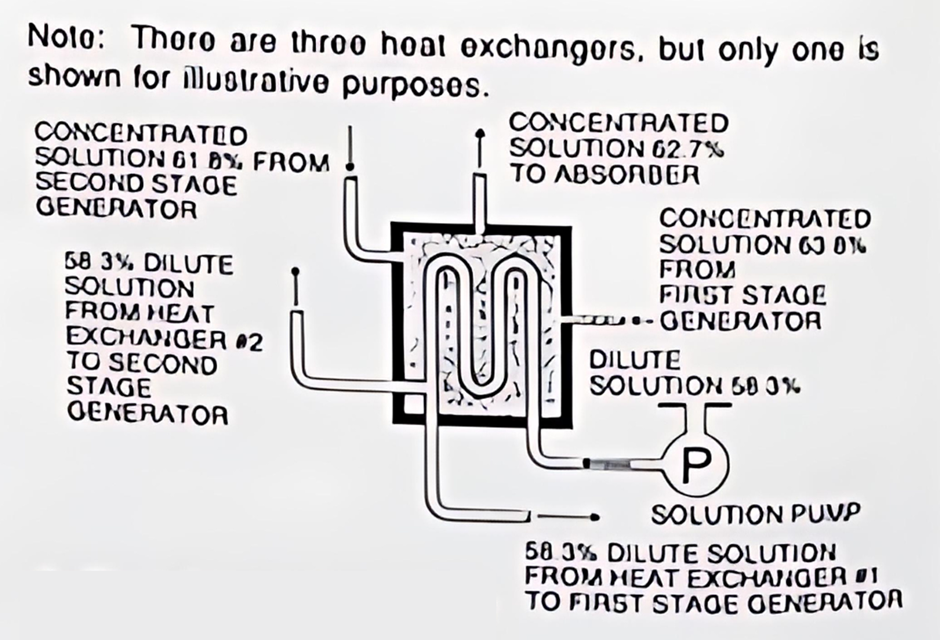

1. Solution Pump/Heat

Exchangers

A dilute solution (58.3%) of lithium bromide and water descends from the Absorber to the Solution Pump. This flow of dilute solution is split into two streams and pumped through heat exchangers to the First-Stage Generator and to the Second-Stage Generator.

Exclusive

two-way split of solution flow virtually eliminates the possibility of

crystallization (solidification) by allowing the unit to operate at much lower

solution concentration and temperatures than series flow systems.

2.

First-Stage Generator

This

produces hot refrigerant vapor which is sent to the Second-Stage Generator, leaving

a concentrated solution (63.8%) that is returned to the Heat Exchangers.

3.Second-Stage

Generator

The energy

source for the production of refrigerant vapor in the Second Stage Generator is

the hot refrigerant vapor produced by the First-Stage

This is the heart of York's remarkably efficient two-stage absorption effect. The refrigerant vapor produced in the First Stage Generator is increased by 40 % at no additional expense of fuel. The result is much higher than in conventional systems.

This

additional refrigerant vapor (dotted arrows) is produced when dilute solution foam

the Heat exchanger is heated by refrigerant “vapor from the First- Stage

Generator,

The

additional concentrated solution (light grey) that results is returned to the

Heat Exchanger. The refrigerant vapor from the First-Stage Generator condenses

into liquid (dark grey) giving up its heat, and continues to the Condenser.

Refrigerant from two sources - (1) liquid (dark grey) resulting from the condensing of vapor produced in the First-Stage Generator and (2) vapor (dotted arrows) produced by the Second-Stage Generator - enters the Condenser. The refrigerant vapor is condensed into liquid and the refrigerant liquid is cooled. The refrigerant liquids are combined and cooled by condenser water. The liquid then flows down to the Evaporator.

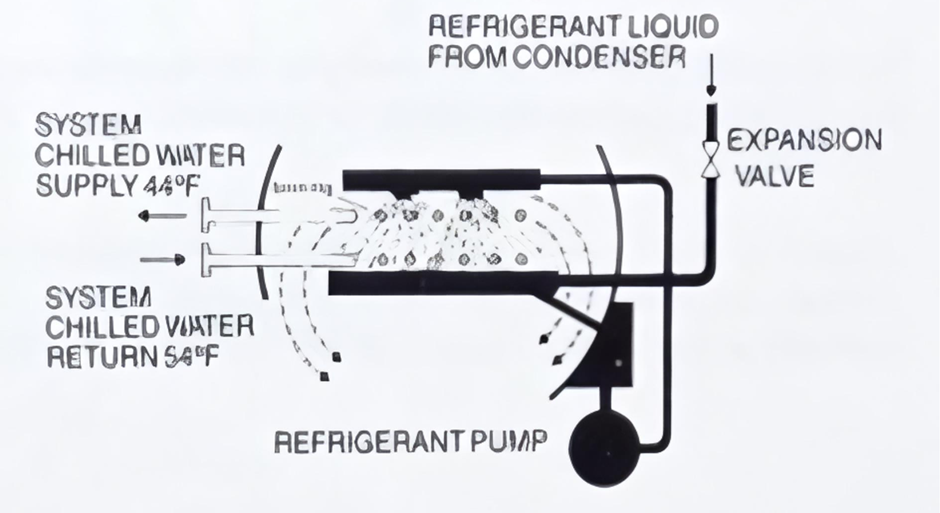

5.Evaporator

The

refrigerant effect cools returning system chilled water in the Evaporator tubes.

The refrigerant liquid /vapor picks up the heat of returning chilled water,

cooling it from 54° F to 44° F. The chilled water is then supplied back to the

system.

As refrigerant liquid/vapor descends to the Absorber from the Evaporator, concentrated solution (62.7%) coming from the Heat Exchanger is sprayed out into the flow of descending refrigerant. The hygroscopic action between lithium bromide and water - and the related changes in concentration and temperature -result in the creation of an extreme vacuum in the Evaporator directly above. The dissolving of the lithium bromide in water gives off heat. which is removed by condenser water entering from the Cooling tower at 85° F and leaving for the Condenser at92° F (black dotted lines). The resultant dilute lithium bromide solution collects in the bottom of the Absorber. where it flows down to the Solution Pump.

Comments

Post a Comment