All About Shell and Tube Heat exchanger

Shell and tube heat Exchanger-

A mechanical Static equipment or device having two different

compartments – shell compartment and tube compartment, where two different

fluids/ media /substance, with different temperature, flow without mixing with

each other to pass a heat from one to another by convection & conduction

Here's how it typically works:

Shell Side /compartment- One fluid flows through the shell,

surrounding a bundle of tubes. This fluid gains or loses heat as it passes over

the outer surface of the tubes. The heat transfer happens through convection

between the fluid in the shell and the outer surface of the tubes.

Tube Side/compartment- The other fluid flows through the

tubes. As it passes through the tubes, it gains or loses heat through

convection with the inner surface of the tubes. Heat is transferred from one

fluid to the other through the tube walls by conduction.

This setup maximizes the surface area available for heat transfer between the two fluids, allowing efficient exchange of thermal energy.

Coming back to shell and tube heat exchanger, a shell is a cylindrical-shaped body, typically a large pipe with a diameter of 4 inches or more. It serves as the outer casing and acts as a pressure vessel.

Distinction by Phases :- Single Phase shell and tube heat

exchanger ,Two Phase Shell and tube heat exchanger

The heat exchanger, where two fluids undergo phase changes

from liquid to gas or vapor form, and from vapor or gas form, condense back

into liquid, is known as a two-phase shell and tube heat exchanger. Examples-

Condensers, Evaporators steam Boilers

In instances where there is no phase change, and liquids

remain in liquid form while gases remain in gas form on both sides of the shell

and tube heat exchanger, this type of heat exchanger is referred to as a

single-phase or one-phase shell and tube heat exchanger. Examples – oil

coolers, air intercoolers aftercoolers.

Geometry & Design :-

The shell and tube heat exchangers are designed and categorized

in three types:-

1)

U Tube Heat Exchanger ( Have only one head /

bonnet & U tubes bundle, both removable )

Heat exchanger with one stationary tube sheet attached to the shell and channel. The heat exchanger contains a bundle of U‐tubes attached to the tube sheet

2)

Fixed Tube Sheet Heat Exchanger (with removable

front & rear heads (Both) )

Heat exchanger with two stationary tube sheets, each attached to the shell

and channel. The heat exchanger contains a bundle of straight tubes connecting

both tube- sheets

3)

Heat exchanger with one stationary tube sheet attached to the shell and

channel, and one floating tube sheet that can move axially. The heat exchanger

contains a bundle of straight tubes connecting both tube sheets

Images source: - ASME

BPVS SEC VIII-1

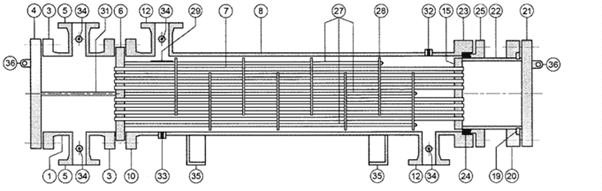

The terminology of shell and tube heat exchanger &

components as given in ASME BPVC sec Viii Div1 is as below:-

1)

Channel cover ( bolted flat cover) 9) Baffles or support plates

2)

Channel 10)

Floating head backing device

3)

Channel flange 11) Floating tube sheet

4)

Pass partition 12) Floating head

5)

Stationery tube sheet 13)

Floating head flange

6)

Shell flange 14) Shell cover

7)

Tubes 15) Expansion joint

8)

Shell 16)

Distribution or vapor belt

"Designations for Shell and Tube Exchangers

Three classes of Mechanical Standards, R, C, and B,

reflecting acceptable designs for various service

applications, are presented. The user should refer to the

definition of each class and choose the one that best fits the specific need.

TEMA CLASS “R” “C” “B” Type Shell and Tube Heat

exchangers

Definition of Class “R” Heat exchanger:-

The TEMA mechanical standard for class “R” heat exchanger

specify Design & Fabrication of unfired shell and tube heat exchangers for

the generally severe requirements of petroleum and process application.

Definition of Class “C” Heat exchanger:-

The TEMA mechanical standard for class “C” heat exchanger

specify Design & Fabrication of unfired shell and tube heat exchangers for

the generally moderate requirements of commercial and general process

application.

Definition of Class “B” Heat exchanger:-

The TEMA mechanical standard for class “B” heat exchanger

specify Design & Fabrication of unfired shell and tube heat exchangers for chemical

process service

The widespread adoption of shell and tube exchangers has led

to the establishment of a standardized naming system developed by the Tubular

Exchanger Manufacturers Association (TEMA). This system utilizes letters and

diagrams to describe various aspects of the exchangers. The initial letter denotes the type of

front header, the second

letter indicates the shell type, and the third letter specifies the rear header type. For

instance, examples like BEM, AEP, AES, and CFU exchangers are illustrated in

below shown Figure 1, Figure 2, Figure 3, and figure 4 while Figure A provides

a comprehensive overview of the complete TEMA nomenclature."

In TEMA standard:- based on front end stationery head , type of shells and rear end head types

classification is as show in below table .

Front end

stationery head types are A,B,C,N and D

Shell

types are E,F,G,H,J,K and X

Rear end

head types are L,M,N,P,S,T,U and W

Bellow given Figure A provides a comprehensive

overview of the complete TEMA nomenclature."

Image Source- TEMA 10th Edition

1)

Stationery Head Channel 21.Floating

head cover External

2)

Stationery Head Bonnet 22. Floating

Tube sheet skirt

3)

Stationery Head Flange Channel or Bonnet 23. Packing box

4)

Channel Cover 24. Packing

5)

Stationery Head Nozzle 25. Packing

Gland

6)

Stationery Tube Sheet 26. Lantern

ring.

7)

Tubes 27. Tierods

and spacers

8)

Shell 28. Transverse

baffle or support plate

9)

Shell Cover 29. Impingement

plate.

10)

Shell flange Stationery Head End 30. Longitudinal

baffle

11)

Shell flange rear head end 31. Pass

partition

12)

Shell Nozzle 32. Vent

Connection

13)

Shell Cover flange 33. Drain

connection

14)

Expansion Joint 34. Instrument

connection

15)

Floating Tube sheet 35. Support

saddle

16)

Floating head cover 36. Lifting

lug

17)

Floating head cover flange 37. Support

Bracket

18)

Floating head backing device 38. Weir

19)

Split shear ring 39. Liquid

Level connection.

20)

Slip on backing Flange 40. Floating

head support

BEM – Bonnet(integral cover) (B

type)+Shell E Type+ Fixed tube sheet like “b” stationery

head(M type)

Figure 1

Image Source- TEMA 10th Edition

AEP- Channel and removable cover (A

type)+ Shell E Type + Outside packed floating head (P

type)

Figure 2

Image Source- TEMA 10th Edition

AES- Channel and removable cover (A

type)+ Shell E Type+ Floating head with backing device (S

type)

Figure 3

Image Source- TEMA 10th Edition

CFU- Channel integral with tube sheet and

removable cover (C type)+ shell F type + U

tube bundle

Figure 4

Image Source- TEMA 10th Edition

Fixed Tube sheet Heat Exchanger :-

In this particular heat exchanger design, the shell and both side tube

sheets are welded together, resulting in the lowest manufacturing cost. This

structural design contributes to its widespread popularity and extensive usage

due to its cost-effectiveness. Cleaning the interior of the tubes involves

removing both end covers or headers/dish ends, facilitating mechanical cleaning

using lengthy brushes and pressurized water. However, cleaning the exterior of

the tubes is limited to chemical methods. To accommodate varying temperature

differentials, expansion joints or bellows are commonly integrated into the

design to withstand thermal expansion effectively.

As illustrated in Figure A above, the rear end head types for the Fixed

Tube Sheet type heat exchanger are labeled as L, M, and N.

The U-tube shell and tube heat exchanger employs 180-degree U-bend tubes

in its manufacturing construction.

As depicted in Figure A, the rear end header types for the Floating Head

type heat exchanger are denoted by the letters P, S, T, and W.

Type A:- Front Header Type A features a header cover

bolted directly onto it, allowing for easy removal of the cover for inspection,

maintenance, and tube cleaning purposes. This design offers the advantage of

not requiring the removal of associated piping for tube cleaning. However, it

requires the use of two gaskets—one for the tube sheet and another for the

cover—as well as double the set of fasteners, making it a more costly design

option.

Type B:- Front Header Type B is characterized by its

requirement of only one gasket joint and one set of fasteners, enabling it to

withstand higher pressures. However, a disadvantage is that it necessitates the

removal of associated piping for inspection, maintenance, and tube cleaning.

Nonetheless, this design option is the least costly among alternatives.

C type front header – it has channel integral with

tube sheet and removable cover along with removable tube bundle with two seal

joints , 2 gaskets , 2 set of fasteners

. header cover bolted directly onto it, allowing for easy removal of the cover

for inspection, maintenance, and tube cleaning purposes. This design offers the

advantage of not requiring the removal of associated piping for tube cleaning

N type front header features a channel integrated

with the tube sheet and shell, along with a removable cover requiring only one

gasket and one set of fasteners. The header cover is bolted directly onto it,

enabling easy removal for inspection, maintenance, and tube cleaning. This

design offers the advantage of not necessitating the removal of associated

piping for tube cleaning.

D-Type front header, designed for very high-pressure

applications, presents challenges in maintenance and is the most expensive

option available. Despite its high cost, this design offers the advantage of

not needing associated piping removal for tube cleaning. However, due to the

integral nature of the tube bundle, maintenance and tube cleaning are intricate

processes

Shell Type E: This design features a simple shell

with one inlet at the top left side and one outlet at the bottom right side,

providing a single pass for the shell-side fluid. It is widely utilized across

various applications.

Rear End Head Types:

L Type: This type features a header cover bolted

directly onto it, allowing for easy removal of the cover for inspection,

maintenance, and tube cleaning. While it offers the advantage of not requiring

the removal of associated piping for tube cleaning, it entails the use of two

gaskets—one for the tube sheet and another for the cover—as well as double the

set of fasteners, making it a more costly design option. It resembles a fixed

tube sheet like A, forming a stationary head.

Now we can further design each based on shell and tube

side passes as –

The configuration of shell and tube heat exchangers can vary

in terms of passes, denoted as 1-1, 1-2, 1-4, and so forth, representing one,

two, four, six, or eight passes, respectively. The first digit indicates the

number of shells, while the second digit indicates the number of passes.

The number of passes signifies how many times the fluid

circulates within the shell. For instance, in a single-pass heat exchanger, the

fluid traverses the shell only once. With each increase in the number of

passes, there's a corresponding increase in the heat transfer coefficient.

1 shell side pass and

1 tube side pass (1-1) - Both the following figures shows this 1-1

type

2 shell side pass and 2 tube side pass – (2-2) .

1 shell side pass and 2 tube side pass - ( 1-2)

In addition to above three we can even go for more than

three passes for tube side as four pass, five pass, six pass, seven pass, eight

pass upto 12 passes. More passes are very common in chillers of HVAC & R as a evaporators /coolers. We

can have these with alternate pass partition placed in both side of head covers

as shown in below diagram

Flow types are an integral part of categorizing shell

and tube heat exchangers based on their characteristics, facilitating

comprehension of their function and operation. One such characteristic is their

flow type.

Shell and tube heat exchangers are categorized into three

flow types: parallel, counter, and cross. These flow types are utilized

in various combinations due to their distinct designs, operational

requirements, and applications.

Parallel flow occurs when both the shell and tube sides enter the heat exchanger from the same end and flow directly towards the opposite end. In this configuration, the temperature change for each fluid is uniform, increasing or decreasing by equal amounts.

Counter flow, on the other hand, involves fluids

flowing in opposite directions, entering the heat exchanger at opposite ends,

and discharging at opposite ends. It is widely regarded as the most popular and

efficient type of heat exchanger due to its superior performance.

Cross flow in a shell and tube heat exchanger entails

fluids flowing perpendicular to each other at a 90-degree angle. One of the

fluids undergoes a change in state, similar to a steam system condenser where

cooling water absorbs steam, before being absorbed by the fluid that remains in

its liquid state.

Now we can further design each based on shell and tube side

circuits as – Typically for evaporators & condensers used in refrigeration

& air-conditioning chillers .

1 shell side circuit and 2 tube side circuit . this is normally in evaporators used in refrigeration & air-conditioning chillers .

1 shell side circuit and 3 tube side circuit this is normally in evaporators used in refrigeration & air-conditioning

chillers .

2 shell side circuit and 1 tube side circuit this is normally in condensers used in refrigeration & air-conditioning

chillers .

The TEMA Mechanical Standards are applicable to shell and

tube heat exchangers that fall below certain criteria:

Inside diameters must not exceed 100 inches (2540 mm).

The product of the nominal diameter (in inches or

millimeters) and the design pressure (in pounds per square inch or kilopascals)

must not exceed 100,000 (17.5 x 10^5).

The design pressure should not exceed 3,000 psi (20684 kPa).

These criteria are set to ensure that the maximum shell wall

thickness remains approximately 3 inches (76 mm), and the maximum stud diameter

is around 4 inches (102 mm).

TUBE Pattern

Triangular Rotated Triangular Square Rotated Square

Please take note in above figure: The flow arrows are

oriented perpendicular to the edge of the baffle cut.

Triangular Pattern :- When mechanical cleaning of the shell

side is required, triangular or rotated triangular patterns should be avoided.

Square Pattern :- In removable bundle units, if mechanical

cleaning of the tubes is requested by the purchaser, the tube lanes should form

a continuous pattern.

Tube Pitch for TEMA mechanical standard for class “R”

- Tube spacing must adhere to a minimum center-to-center distance of 1.25 times

the outside diameter of the tube. In instances where mechanical cleaning of the

tubes is requested by the purchaser, minimum cleaning lanes of 1/4" (6.4

mm) should be included.

Tube Pitch for TEMA mechanical standard for class “C”-

Tubes should be positioned with a minimum center-to-center distance of 1.25

times the outside diameter of the tube. However, in cases where the tube

diameters are 5/8" (15.9 mm) or smaller and tube-to-tube sheet joints are

solely expanded, the minimum center-to-center distance can be reduced to 1.20

times the outside diameter.

Tube Pitch for TEMA mechanical standard for class “B”-

Tubes must maintain a minimum center-to-center distance of 1.25 times the

outside diameter of the tube. If the purchaser specifies mechanical cleaning of

the tubes and the nominal shell diameter is 12 inches (305 mm) or less, minimum

cleaning lanes of 3/16" (4.8 mm) should be included. For shell diameters

exceeding 12 inches (305 mm), minimum cleaning lanes of 1/4" (6.4 mm) are

required.

Tube Length :- Commonly used tube lengths for

both straight and U-tube heat exchangers include: 96 inches (2438 mm), 120

inches (3048 mm), 144 inches (3658 mm), 192 inches (4877 mm), and 240 inches

(6096 mm).

Bare Tube Sizes :- Birmingham Wire Gage (BWG) standard

Tube wall thickness must be designated as either minimum or

average.

For integrally finned tubes:

The nominal fin diameter must not surpass the outside

diameter of the unfinned section.

Tubes must be specified with both the thickness under the

fin and at the plain end.

Baffles & Suport Plates :-

In a shell and tube heat exchanger, baffles are used to

direct the flow of fluid within the shell side of the exchanger. As the shell

fluid circulates around the tubes, directed by baffles, the motion of the shell

fluid—whether it's lateral or vertical—and the number of times it traverses

over the tubes, are regulated by segmental baffles. These baffles play a vital

role in optimizing heat transfer efficiency. They are typically perforated

plates or rods placed perpendicular to the tube bundle. Baffles serve several

purposes:

Enhanced Heat Transfer: By causing the fluid to flow

around the tubes in a specific pattern, baffles promote turbulence, which

increases heat transfer efficiency.

Prevention of Fluid Channeling: Baffles help prevent

fluid from taking a direct path through the exchanger, ensuring that it is

evenly distributed across the tube bundle. This helps in maximizing heat

transfer rates and avoiding hot spots or cold spots.

Structural Support: Baffles also provide structural

support to the tube bundle, helping to maintain its alignment and integrity,

especially in high-pressure applications.

Tube Alignment: Support plates ensure proper

alignment of the tubes within the tube sheet, preventing them from sagging or

vibrating excessively, which could lead to mechanical failure or reduced heat

transfer efficiency.

Overall, baffles and support plates play crucial roles in

optimizing the performance and structural integrity of shell and tube heat

exchangers, ensuring efficient heat transfer while maintaining mechanical

stability.

Baffle Cuts for segmental baffle :-

Horizontal Vertical Rotated

Baffle Cuts for Multi -Segmental baffle :-

Double Segmental

Triple segmental

The segmental or multi-segmental type of baffle or tube

support plate is standard, although other types of baffles are allowed. The

baffle cut is defined as the opening height of the segment expressed as a

percentage of the shell inside diameter or as a percentage of the total net

free area inside the shell (which is the shell cross-sectional area minus the

total tube area).

For multi-segmental baffles, the number of tube rows that

overlap should be adjusted to ensure approximately equal net free area flow

through each baffle. Baffles should be cut near the centerline of a row of

tubes, a pass lane, a tube lane, or outside the tube pattern. Moreover, baffles

should have a satisfactory machined finish on the outside diameter.

Typically, baffle cuts can be vertical, horizontal, or

rotated, as illustrated in the figure above.

When determining the maximum and minimum

spacing for baffles/support and unsupported tube lengths, it's essential to

engage a designer proficient in the thermal/hydraulic design of shell and tube

heat exchangers. Various factors such as operating conditions, heat load,

prevention of flow-induced vibration, available tube length, and nozzle

locations must be considered when establishing the spacing of baffle and

support plates.

For minimum spacing, segmental baffles typically should not

be positioned closer than 1/5 of the shell inside diameter or 2 inches (51 mm),

whichever is greater. However, specific design requirements might necessitate a

closer spacing.

Baffles normally shall be spaced uniformly, spanning the

effective tube length. When this

is not possible, the baffles nearest the ends of the shell,

and/or tube sheets, shall be located

as close as practical to the shell nozzles. The remaining

baffles normally shall be spaced

uniformly.

Tie Rod & Spacers :-

To ensure the secure positioning of all transverse baffles

and tube support plates, tie rods and spacers, or alternative methods with

equivalent effectiveness, must be implemented to tie the baffle system together

and securely in position.

It is recommended to use a specific number and diameter of

tie rods based on the size of the heat exchangers. Alternative combinations of

tie rod count and diameter with equivalent metal area are acceptable. However,

a minimum of four tie rods and a diameter no smaller than 3/8" (9.5 mm)

must be utilized. Additionally, each baffle segment requires at least three

points of support.

The suggested number of tie rods based on the size of the

shell diameter is as follows:For shell

sizes up to 14 inches: 4 tie rods

For shell sizes from 16 inches to 33 inches: 6 tie rods

For shell sizes from 34 inches to 48 inches: 8 tie rods

For shell sizes from 49 inches to 60 inches: 10 tie rodsFor shell sizes from 61 inches to 100 inches: 12 tie rods TIE RODS

SPACER TUBES

BAFFLE ASSLY

Impingement protection is crucial for shell side

inlet nozzles to safeguard the tube bundle against impinging fluids.

An Impingement insert means needed to prevent or minimize

erosion of tube bundle components at the entrance and exit areas.

In this section, v is defined as the linear velocity of the

fluid in feet per second (meters per second)

and p is its density in pounds per cubic foot (kilograms per

cubic meter)

However, if the product of ρv2 in the inlet nozzle falls below the specified

limits, impingement protection may not be necessary:

1500 (2232) for non-abrasive, single-phase fluids (liquids,

gases, or vapors).

500 (744) for all other liquids, including those at their

boiling points.

For all other gases, vapors (including steam), and

liquid-vapor mixtures, impingement protection is required.

A well-designed diffuser can effectively reduce line

velocities at the shell entrance. Distributor belt type diffusers may be

utilized for this purpose.

Expansion Joint :-

An expansion joint in a shell and tube heat exchanger serves

a crucial function in accommodating thermal expansion and contraction of the

tubes. As the heat exchanger operates, the metal tubes are subjected to changes

in temperature, causing them to expand and contract. Without an expansion

joint, these thermal movements could lead to stress build-up, deformation, or

even damage to the tubes and other components of the heat exchanger.

Expansion joints are typically installed at specific locations within the tube bundle assembly where thermal movement is expected to occur normally in shell. These joints consist of flexible elements, such as bellows or corrugated sections, which can flex and elongate in response to the changes in tube length due to temperature variations. By absorbing the thermal expansion and contraction of the tubes, the expansion joint helps to reduce mechanical stresses on the heat exchanger components and ensures the integrity of the system over its operational lifespan.

In summary, expansion joints are essential components in

shell and tube heat exchangers, providing flexibility to accommodate thermal

expansion and contraction of the tubes, thereby preventing damage and

maintaining the efficiency and reliability of the heat exchanger.

The

shell of the exchanger needs safeguarding from over-pressure through the use of

pressure relief valves (PRV). The timing of these protective devices'

activation has been identified as crucial for the effective protection of the

exchanger from high pressures than designed. These safety mechanisms are

installed directly onto the exchanger's shell and release pressure into a

relief system.

Fluid Allocation :-

Fluid distribution:

Place the high-pressure stream within the tubes. Opt for

high-pressure and high-temperature fluids on the tube side for optimal cost design.

Position corrosive, hazardous and toxic fluids , freezing

fluids within the tubes.

Allocate the stream with the highest fouling tendency to the

tube side.

Direct more viscous fluids to the shell side.

Assign streams with lower flow rates to the shell side.

Allocate fluids requiring low pressure drop during operation to the shell side

due to its larger flow area and lower resistance.

Place fluids undergoing phase change or transitioning from

gas / vapor/liquid on the shell side.

Route streams with lower heat transfer coefficients to the

shell sideand high heat transfer coefficient in tube side.

Place toxic fluids within the tubes.

Thermal Design:-

The thermal design process for a heat exchanger involves

several key steps:

Definition of Operating Conditions: Determine the

design temperature, pressure, and maximum allowable pressure drop for both the

product and service fluids.

Fluid Properties Analysis: Analyze the physical

properties of the fluids involved, including density, specific heat, thermal

conductivity, and viscosity.

Customer Input: Typically, the customer specifies the

product's flow rate and desired entry and exit temperatures. Two out of three

parameters (flow rate, entry temperature, exit temperature) are provided, and

the third is calculated accordingly.

Geometry Definition: Define the heat exchanger's

geometry, including the shell diameter, tube bundle specifications (number of

inner tubes, inner tube diameter, wall thickness, and length), and dimensions

of shell and tube side fluid connections. Material selection is also determined

at this stage.

Thermal Calculation: Perform thermal calculations to

determine the heat transfer coefficients for both the shell and tube sides.

These coefficients are influenced by fluid properties and flow velocity. Using

specific formulas tailored to the heat exchanger type, calculate the overall

heat transfer coefficient. This value is used to calculate the total heat

transfer area required for the application using the formula: Area = Duty / (K × LMTD),

where Duty is the total heat transferred, K is the overall heat transfer

coefficient, and LMTD is the log mean temperature difference.

Pressure Drop Calculation: Calculate the pressure

drop for both the shell and tube side fluids, considering factors such as

Reynolds number, flow type (turbulent or laminar), and roughness values of the

shell and inner tubes.

Interpretation of Thermal Calculation: Compare the

calculated heat transfer area with the predefined area. If the calculated area

exceeds the predefined area, consider redesigning the heat exchanger geometry

by adjusting parameters such as length or adding inner tubes. Similarly, if the

calculated pressure drop exceeds the maximum defined, redesign the geometry to

reduce pressure drop.

Iterative Process: Repeat above steps as necessary

until a satisfactory design with suitable geometry and within design limits is

obtained.

This process ensures that the heat exchanger is designed to efficiently

transfer heat while meeting the specified operating conditions and constraints.

Mechanical Design:-

the mechanical design calculations ensure its structural

integrity and compliance with design pressure and conditions. These

calculations typically include:

Shell Wall Thickness Calculation: Determine the

required thickness of the shell to withstand the design pressure and maintain

structural integrity.

Nozzle Wall Thickness Calculation: Calculate the

thickness of the nozzle walls to ensure they can withstand the pressure and

loads applied at the connections.

Inner Tube Wall Thickness Calculation: Determine the

thickness of the inner tube walls to withstand the pressure and thermal

stresses.

Expansion Joint Dimensions Calculation: Calculate the

dimensions of the expansion joints to accommodate the differential expansion

between the shell and tube sides due to temperature differences.

Tube Sheet Thickness Calculation: Determine the

thickness of the tube sheet to support the tube bundle and withstand pressure

and thermal stresses.

The mechanical design calculations may reveal parameters

that do not align with the initial geometric design. In such cases, a new

proposal for the geometry may be necessary, requiring repetition of steps four

to seven.

Once all dimensions are finalized, manufacturing drawings

are prepared which include detailed specifications of various components such

as the shell, tubes, expansion joints, and connections, ensuring accurate

fabrication of the heat exchanger.

A Brief about Material of construction ( MOC)

Shell and Tube Sheets:- shell material should also be

able to withstand the operating conditions, including temperature, pressure,

and potential corrosive environments. Common materials for the shell include

carbon steel, stainless steel, and various alloys.

End Covers or Heads:-The end covers or heads seal the

ends of the shell and are typically removable for maintenance and inspection.

These components must be made from materials that provide a tight seal and can

withstand the mechanical stresses and operating conditions. Materials commonly

used for end covers include carbon steel, stainless steel, and alloy steels.

Tubes:- The selection of tube material is crucial for

effective heat transfer. Good thermal conductivity is essential for efficient

heat transfer, as heat moves from a hotter side to a colder side through the

tubes, creating a temperature gradient along their length. Moreover, the tube

material must be able to withstand thermal expansion differences at varying

temperatures, which can induce thermal stresses during operation, alongside

potential stress from fluid pressures. Furthermore, the chosen material should

be compatible with both the fluids on the shell and tube sides over prolonged

periods under operating conditions (including temperatures, pressures, and pH

levels) to prevent deterioration such as corrosion. Therefore, it's imperative

to carefully choose robust, thermally conductive, corrosion-resistant materials

of high quality, typically metals like aluminium, copper alloys, stainless

steel, carbon steel, non-ferrous copper alloys, Inconel, nickel, Hastelloy, and

titanium. Additionally, fluoropolymers and Fluorinated ethylene propylene are

utilized for tubing material due to their exceptional resistance to extreme

temperatures.

Here are the uses and industries associated with each of

the listed shell and tube heat exchanger applications:

- 1) Condenser - Uses: Condenses vapor into liquid; Industry: HVAC, refrigeration, power generation.

- 2) Evaporator - Uses: Evaporates liquid into vapor; Industry: Refrigeration, food processing, chemical processing.

- 3) Oil Cooler - Uses: Cools oil or other fluids; Industry: Automotive, industrial machinery, hydraulic systems.

- 4) Intercooler - Uses: Cools compressed air between turbocharger stages; Industry: Automotive, marine, aerospace.

- 5) Aftercooler - Uses: Cools compressed air after compression; Industry: Air compression systems, power generation, refrigeration.

- 6) Refrigerant Cooler - Uses: Cools refrigerant fluids; Industry: HVAC, refrigeration, chemical processing.

- 7) Steam Generator - Uses: Produces steam from water; Industry: Power generation, industrial processes, steam systems.

- 8) Boiler Feedwater Heater - Uses: Heats feedwater before entering a boiler; Industry: Power generation, boiler systems.

- 9) Gas Cooler - Uses: Cools gases in various industrial processes; Industry: Petrochemical, chemical processing, power generation.

- 10) Brine Cooler - Uses: Cools brine solutions in refrigeration systems; Industry: Refrigeration, cold storage facilities, food processing.

- 11) Process Heater - Uses: Heats gases or liquids in industrial processes; Industry: Chemical processing, petroleum refining, food processing.

- 12) Air Preheater - Uses: Heats combustion air in power plants and industrial boilers; Industry: Power generation, boiler systems, industrial processes.

- 13) Cooling Tower Water Heater - Uses: Heats water in cooling towers; Industry: HVAC, power generation, industrial cooling systems.

- 14) Heat Recovery Steam Generator (HRSG) - Uses: Recovers heat from exhaust gases to generate steam; Industry: Power generation, combined cycle power plants.

- 15) Hydraulic Oil Cooler - Uses: Cools hydraulic fluid in hydraulic systems; Industry: Automotive, aerospace, industrial machinery.

- 16) Lubricating Oil Cooler - Uses: Cools engine lubricants; Industry: Automotive, industrial machinery, marine.

- 17) Chemical Reactor Cooler - Uses: Controls temperatures in chemical reactions; Industry: Chemical processing, pharmaceuticals, petrochemicals.

- 18) Waste Heat Recovery Unit (WHRU) - Uses: Recovers waste heat from industrial processes; Industry: Energy production, chemical processing, manufacturing.

- 19) Marine Heat Exchanger - Uses: Cools marine engine coolant; Industry: Marine, shipping, offshore drilling.

- 20) Ethylene Glycol Heater/Cooler - Uses: Heats or cools ethylene glycol in HVAC systems; Industry: HVAC, refrigeration, chemical processing.

- 21) Heat Recovery Exchanger - Uses: Recovers waste heat for reuse; Industry: Industrial processes, power generation, chemical processing.

- 22) Feedwater Preheater - Uses: Preheats boiler feedwater; Industry: Power generation, boiler systems, industrial processes.

- 23) Ammonia Cooler - Uses: Cools ammonia gas or liquid; Industry: Refrigeration, chemical processing, food processing.

- 24) Chlorine Cooler - Uses: Cools chlorine gas; Industry: Chemical processing, water treatment, disinfection.

- 25) Glycol Reboiler - Uses: Re-boil glycol used in natural gas dehydration; Industry: Oil and gas, chemical processing, petrochemicals.

- 26) Heater Treater - Uses: Heats and separates oil-water emulsions; Industry: Oil production, petroleum refining, chemical processing.

- 27) Thermal Oil Heater - Uses: Heats thermal oil for industrial heating systems; Industry: Chemical processing, asphalt plants, food processing.

- 28) Deaerator - Uses: Removes dissolved gases from boiler feedwater; Industry: Power generation, boiler systems, chemical processing.

- 29) Feedwater Heater - Uses: Heats feedwater before entering a boiler; Industry: Power generation, boiler systems, industrial processes.

- 30) Gas-to-Gas Heat Exchanger - Uses: Transfers heat between two gas streams; Industry: Chemical processing, power generation, gas purification.

- These descriptions provide insight into the specific uses and industries where shell and tube heat exchangers are commonly employed.

Standards & Regulations :-

The codes applicable for shell and tube heat exchanger

design & manufacturing.

1) ASME American Society of

Mechanical Engineers, Boiler and Pressure Vessel Code (BPVC) Sec VIII Div 1

Part UHX

2)TEMA is the Tubular Exchanger Manufacturers

Association- most widely accepted and used.

3)API 660 API standards relate to the manufacturing

of equipment and parts for the oil and gas industry

4) IS 4503 : 1967 indian standard

5) Canadian Registration Number. CRN - required for

any boiler, pressure vessel will be in operation in Canada

5) PED Pressure Equipment Directive (PED) is

mandatory in the European Union when manufacturing pressure equipment, or

selling it into the EU

6) NORSK - Standards are by the Norwegian petroleum

industry essential for manufacturing heat exchangers to sell in Norway.

These regulations and standards play a crucial role in

ensuring the safety, reliability, and compliance of shell and tube heat

exchangers across various industries and regions.

References:-

• Standards

of the Tubular Exchanger Manufacturers Association (TEMA), 10th edition, 2019

• ASME

Boiler and Pressure Vessel Code, (BPVC) Section VIII, Division 1, Part UHX

Comments

Post a Comment