Heat Exchangers Specific Applications and General Maintenance

Heat exchangers Specific Applications and General Maintenance.

The heat exchangers we have seen up to now

have all been used to heat, a process liquid in some instances.

However, the purpose of heat exchange is

to remove heat from a fluid that requires cooling.

Suppose we wanted to convert steam

generated by one process into feed water for another process. To do this a shell and tube exchanger can be

used as a condenser.

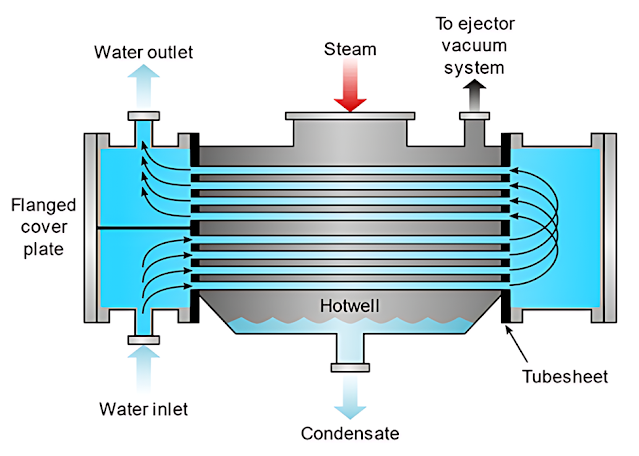

This cutaway will show how the condenser

works.

Water enters the space between the head

of the shell and the adjacent tube sheet and flows through the tubes to the

opposite end. Steam enters at the top of

the shell and flows down and between the condenser's tubes.

When the steam is cooled it condenses to

water and falls into the hot well at the bottom of the condenser.

Air also may be used to cool steam. Here

a fan blows air across tubes that carry steam.

Although not as efficient as water the

air absorbs heat from the steam and the steam condenses an air-cooled system

may be used if water is scarce.

Another application for heat exchangers

is as a Reboiler.

Reboilers are used in systems that heat

and vaporize hydrocarbons.

This one is a kettle type reboiler. It

is simply a shell and tube exchanger surrounded by an enlarged shell that

accommodates vapor.

Let's examine the system.

This system includes a distillation

tower a furnace and a kettle type reboiler.

The furnace heats oil which is pumped

through the tubes of the reboiler.

Meanwhile liquid isobutane flows from

the bottom of the distillation column into the shell of the reboiler.

The heat from the oil is transferred

through the tube walls and vaporizes some of the isobutane.

The isobutane vapors are then channeled

into the distillation column.

These vapors provide the heat needed

for distillation to take place.

Coolers are heat exchangers too.

As the name implies coolers lower the

temperature of the liquid or vapor

In the next example kerosene is being

cooled before going to storage.

Cooling water passes through the

exchanger twice while the kerosene makes only a single pass.

As the kerosene moves through the

exchanger it releases some of its heat to the water.

The horizontal segmental baffles keep

the flow of the kerosene turbulent ensuring maximum contact between the

kerosene and the tubes.

With this contact ensured the kerosene

is cooled efficiently and can then be stored safely.

The final application that we'll look at

is one that converts waste heat into valuable steam.

The heat exchanger used for this purpose

is called a waste heat reboiler.

Let's look at a diagram of a typical

waste heat system.

The main components are a steam drum a

waste heat boiler and a distillation column.

Water from the steam drum is sent

through the tubes of the waste heat boiler while hot oil from the bottom of the

distillation column moves through the shell as water absorbs heat from the oil

part of it is vaporized and turns to steam.

The steam carries small droplets of

water through the boiler.

This mixture of steam and water droplets

flows up into the steam drum

Here the two fluids are separated from

one another.

The steam is sent to the plant steam

system while the water is channeled back to the boiler.

As you know all the equipment involved

in these applications requires periodic maintenance.

For this reason we will now discuss

some basic operating problems and how to handle them.

Fouling is a common and destructive enemy of heat exchange.

A low-velocity flow can start the

build-up of deposits on internal surfaces.

These deposits can cause changes in

temperature and pressure.

The deposits have several sources.

Process fluids may contain solid sediments.

Once they settle a restriction to the

flow develops and the restriction then causes more settling.

Corrosion is produced when the metal of

the exchanger interacts chemically with the process stream.

These deposits can break free eventually

and foul the exchanger tubes.

The warm exchanger provides a

comfortable environment for the growth of certain organisms.

The tube surfaces may become

contaminated with algae.

There are several ways to control

fouling in a heat exchanger.

One way is to add dispersants.

These will prevent insoluble materials

like dirt from forming solid deposits.

Another control method is to add

chemical inhibitors that will keep chemical reactions from taking place Or anti-foulants can be added to the

process streams.

These chemicals prevent biological

growth.

After fouling has occurred, removal

methods depend on the type and severity of the deposits.

Deposits on the outside of tubes can

often be removed by hydro blasting.

A high-pressure stream of water

that loosens and washes away the deposits. Streams of water or steam can

also move the deposits from the inside of a tube.

If water and steam fail, chemical

cleaning may dissolve the deposits.

If, however, the deposits resist both

chemical cleaning and hydro blasting

The exchanger must be completely

dismantled and the deposits scraped off.

At this point it may be best to re-tube

the exchanger

As always, during shutdown and startup, workers

must follow safety precautions

Nitrogen and other inert gases are used

to purge the exchanger of hydrocarbons in air.

These gases can get trapped inside the

exchanger where they interfere with the heat transfer process.

These gases can be released by venting

according to the procedure specific to your unit.

Condensers are susceptible to problems

caused by other gases as well.

One problem occurs when air leaks

restrict the flow of water by causing vapor binding. To eliminate vapor binding, open the vent in

the water exit line.

Another problem is a reduction in

cooling capacity.

This can occur when non-condensable

gases are present in the process side of the condenser.

You can correct this type of problem by

venting the process side of the condenser to release the trapped vapors.

Leaks are another important maintenance concern.

Whenever exchangers are down for

cleaning, they are almost always tested

for leaks.

But before dismantling the exchanger, there

are some preliminary tests you can perform.

One simple way to test for leakage is to take a sample of the lower pressure fluid and check it for contamination, If the fluids are very different in appearance, like oil and water, just looking at the sample should tell you if there is a leak.

This sample, for example, has a small

amount of oil in the water line, a sure sign of a leak.

However, if the fluids are very similar

in appearance, chemical testing may be needed to detect the results of a leak. This

must be done in the lab.

If neither the visual nor the chemical

tests are conclusive, a test using high pressure water may be done. This

is called hydrostatic testing.

Before it can be done, the exchanger

must be taken offline and drained.

If you're checking for tube side

leakage, the tubes are filled with water under pressure. If the tubes or joints

are leaking, the water will be forced through the leak points into the shell.

If tests indicate a leak, the exchanger

must be partially dismantled to determine its source.

To find a leaking tube, the shell is

filled with water under pressure. This water will enter the tube at the point

of the leak and then run out the tube end. By watching the tube sheet, you can

often tell exactly which tube is leaking.

These procedures will help ensure proper

operations and warn of problems before the situation gets out of hand

In this program, you have seen that heat

exchangers can meet the plant's needs efficiently depending on their design for

both heating and cooling purposes. You have also seen the importance of regular

maintenance.

“Thanks for Reading!”

Comments

Post a Comment