Heat Exchanger: - Factors affecting their efficiency and Design, including internal flow arrangements.

Heat Exchanger: - Factors affecting their efficiency and Design, including internal flow arrangements.

In this blog you will learn about heat exchanger: - factors

affecting their efficiency and design including internal flow arrangements.

The program addresses problems that arise when using tube heat

exchangers, which are the most prevalent type, and provides solutions to these

issues.

There are several designs for heat exchangers in addition these

designs are varied as necessary.

Depending upon the characteristics of the process fluid in general

there are plate type heat exchangers and tube heat exchangers

Each transfer’s heat from one fluid to another.

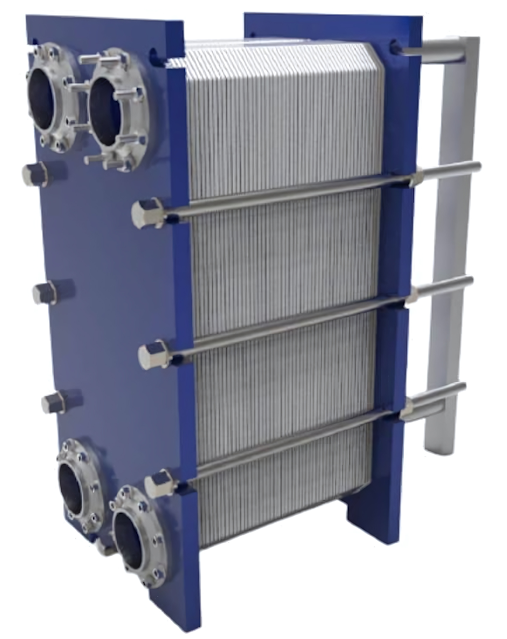

It's made of corrugated plates the plates are held together with an

external pressure plate that can be moved for maintenance and cleaning.

Large surface areas and the natural turbulence caused by the

corrugated metal plates allow for efficient heat transfer.

Plate heat exchangers may be used because of the specific demands

put on the system by the characteristics of the process chemicals. For example,

for a highly corrosive chemical that must be cooled a titanium plate heat

exchanger may be best.

It's design consists of a set of metal tubes carrying one fluid and

the space around those tubes known as the shell carrying another fluid. As we'll see the internal arrangement of the

tube heat exchanger is critical for efficient heat transfer to increase the

amount of heat transfer the tube side fluid can be put through the exchanger

more than once.

To do this a channel baffle or pass partition plate is built into

the head of the exchanger.

Increasing the number of tube side passes improves the efficiency

of an exchanger.

The shell side flow can also be changed to produce high efficiency.

Another arrangement involves segmental baffles.

They can be cut vertically or horizontally and their position to

face in alternate directions. These baffles will allow the fluid to flow across

the tubes a number of times and keep the fluid turbulent.

The more turbulence the more energy is transferred.

If the liquid is dirty the sediment will often build up behind a

horizontal baffle. This decreases efficiency by blocking the flow.

If the force of the fluid entering the shell is too great,

impingement baffles may be used. These baffles direct flow to the sides of the

exchanger which reduces internal erosion. In addition, the fluid contacts more

surface area and increases efficiency

Despite careful design considerations, there are some problems that

occur whenever two fluids with different temperatures run through the same

piece of equipment.

This is because metal expands and contracts in length because of

changes in the temperature.

Even under normal operating conditions this natural process will

stress certain parts of the exchanger.

Whenever these parts expand and contract the tube joints undergo

stress.

Eventually this stress may cause leaks to develop at the tube

joints.

There are basically three designs that deal with the possibility of

leakage.

Some fixed tube sheet exchangers the tube bundle is anchored

between double tube sheets. If a leak does occur the fluid flows into the space

between the tube sheets and can be safely drained from the exchanger. This design may lessen the effect of a leak.

But it cannot lessen the stress that thermal expansion puts on the

tubes a fixed tube sheet exchanger can only be used where the temperature

difference between the two fluids is small.

The next example is a tube bundle from a U Tube exchanger. In this

type, the tubes are free to expand because they're only attached at one end of

the tube sheet.

Although the U Tube bundle can be removed from the shell the bends

in the tubes hinder internal inspection and cleaning.

A third type of exchanger is designed to allow both thermal

expansion and easy maintenance.

Because only one tube sheet is fixed while the other floats

horizontally.

The tubes are free to expand and contract in response to the

temperature changes without stressing the joints and the bundle and floating

head, can be removed for cleaning an inspection when necessary.

This cutaway view of a floating head exchanger shows you one

disadvantage of its design. There is a clearance space between the shell and

tubes, it’s needed so that the bundle can be removed for maintenance. The shell side liquid will tend to flow

through this space an area that offers little resistance. When this happens,

Efficiency decreases because the shell side fluid does not come into contact

with enough tube surface.

We've covered a lot of material in this section dealing with the

internal flow arrangements and problems that may occur.

To summarize there are several types of baffles that affect flow -

channel head baffles, longitudinal baffles, segmental baffles and impingement baffles.

Expansion and contraction cause stress this can be managed in

several ways with the double tube sheet to collect leaks, with a U Tube

exchanger to allow for expansion and the floating head exchanger which makes

cleaning and inspection easy.

In discussing heat exchangers thus far we've examined factors that

affect their efficiency and we've looked at design issues.

Comments

Post a Comment