Understanding and Explaining Engineering Drawings of a Shell and Tube Oil Cooler

Intricate Details of Engineering Drawings for a Shell and Tube Oil Cooler

Shell and tube heat exchangers are pivotal in industrial

heat transfer applications. This blog post will guide you through the intricate

details of reading and understanding the engineering drawings of these

essential devices, focusing on oil coolers.

Components and Structure

Shell and tube heat exchangers consist of several key components: the shell, tube bundle, tube sheets, baffles, and end caps. Each part plays a crucial role in the heat transfer process and the overall functionality of the exchanger.

Reading the Engineering Drawing

Overview

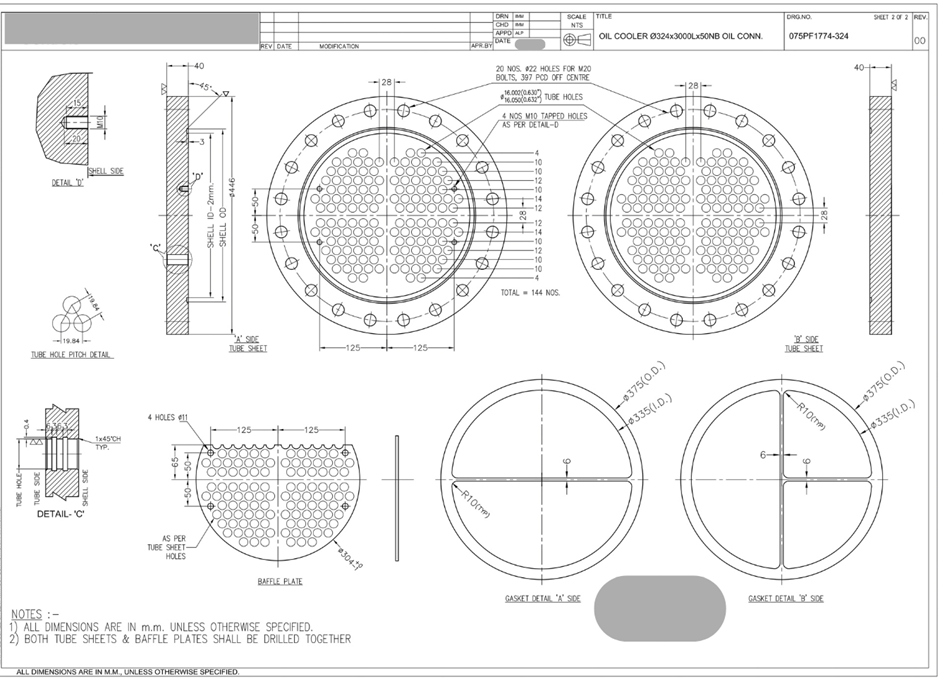

The document shown above is an engineering drawing of a Shell

and tube oil cooler.

Engineering drawings typically use multiple views to represent the object.

Let's start with the title block and general information.

1. Title Block and General Information

The title block usually contains critical information about the drawing, such as:

Drawing Title: Identifies the component or assembly.

Drawing Number: A unique identifier for the drawing.

Date: When the drawing was created or revised.

Drawn by / Checked by / Approved by: Names or initials of

the responsible personnel.

2. Views and Projections

The drawing should include several views:

Front View

Side View

Cross sectional View

Detailed View

These views help in visualizing the oil cooler from different angles.

3. Tables and Charts:

Design Data

Material of Construction

Components item thickness

Nozzle schedule

Special Note

Let's begin by examining the drawing to extract key

measurements and specifications.

Detailed Breakdown of the Oil Cooler Drawing

Shell Dimensions

Length of Shell: 3000 mm [Including both side tube sheet thickness, Tube sheet to tube sheet dimension]

Thickness of Shell: 8 mm [Shown in the table given at

bottom of drawing sheet 1 of 2, mentions item numbers and their respective

thickness]

Diameter of Shell: 324 mm [Outside Diameter] This is 12” seamless

pipe.

Material of Construction: SA 106 Gr B Sch 30[Seamless Pipe Material]

shown in material chart of drawing sheet 1 of 2.

Tube Specifications

Number of Tubes: 144 Numbers [Shown in tube sheet drawing sheet 2 of 2]

Outer Diameter (OD) of Tubes: 15.9 mm [Specify OD]

Tube Gauge: 1.65 mm thk [some drawings Specify it as 16 BWG

which is 1.65 mm thk]

Material of Construction: SA179 C.S.[Carbon Steel Material]

shown in material chart .

Additional Details – Tubes are plain tubes

Tube Sheet Specifications

Number of Tubes: 144 Numbers

Outer Diameter (OD) of Tube Sheet: 446 mm x 40 mm finish thickness

Tube Hole Size: 16.002 to 16.050 mm [16.002 mm is Go gauge size and 16.050mm is No

gauge size for manufacturing and inspection. Thus this is range in between all 144

number of hole should have dimension ]

Material of Construction: SA516 Gr 70 - shown in material

chart .

Tube Hole pitch – 19.84 mm Triangular pitch 60 degree.

Tube Hole Groove- Inside double groove of 3mm wide x 0.04

mm deep x 6mm spacing in between second groove starting at 6 mm from outer

surface of tube sheet as shown in detail C

Pitch Circle Bolts – 20 number holes of 22 mm diameter to

suit M20 bolts on 397 mm PCD Off center.

Tapped holes – 4 number M10 blind tapped holes 15mm deep as

per detail section D for tie rods. This is only on A side tube sheet. B side

tube sheet do not have these tapped holes.

Groove for shell – Shell Id minus 2 mm i.e. 306 mm ID and 324

mm OD groove to insert shell in it for shell to tube sheet joint welding.

Baffle :- 26 number baffles of CRCS sheet 1.6mm thickness of 304 mm OD Spacing at 100mm typical first baffle starting with 250mm from B side tube sheet.

Oil -Inlet and Outlet Dimensions: Nozzle schedule chart

shows oil Inlet and oil outlet 50NB Sch 40 pipe

Water -Inlet and Outlet Dimensions: Nozzle schedule chart

shows water inlet and water outlet 65NB Sch 40 pipe with flanges ANSI B16.5

Class 150

Type of Dish End Caps: Ellipsoidal 2:1, Material 8 mm

thickness SA516 Gr 70

Girth Flanges: Both side girth flanges 48 mm finish

thickness of 446 mm OD of SA516 Gr70 material.

Tie Rods: size M10 with lock nut , material A36

Spacer Tube:- Size 16mm OD x 1mm Thk Tubes, Material Sa 179

Fasteners: M20 Hex bolts with nut and spring washer , quantity

40 numbers, material SA193 Gr B7

Gasket : AF-120 mm material of 3 mm thickness as per sketch dimension shown in drawing sheet 2 of 2. A side and B side gasket are different as suitable for four pass water flow.

Tube Expansion Detail : Length of expansion is tube sheet thickness less 3 mm

Design Data:

Design Code: ASME Sec VIII Div 1 and TEMA.

Fluid : shell side Oil+R717 and tube side – water

Design Pressure: shell side 21 kg/cm2 (Gauge) and tube side

10 kg/cm2 (Gauge)

Design Temperature: shell side 100 degree Celsius and tube

side 60 degree Celsius

Test Pressure: shell side 23.1 kg/cm2 (Pneumatic -by Dry

Nitrogen) and tube side 13.5 kg/cm2 (Hydrostatic- by water)

By breaking down each section of the drawing, you can

understand the design and specifications of the oil cooler. This detailed

explanation can be used to interpreting engineering drawings of shell and tube

heat exchangers.

Thanks for Reading!

Let me ask you few question to you :-

How many water passes are in this drawing? and how do you find it in drawing?

You can comment below . Happy Learning !😕

Comments

Post a Comment